Scan your phone once

As one of the leading powder coating line manufacturers and suppliers in China, we warmly welcome you to buy high-grade powder coating line for sale here from our factory. All our products are with high quality and competitive price.

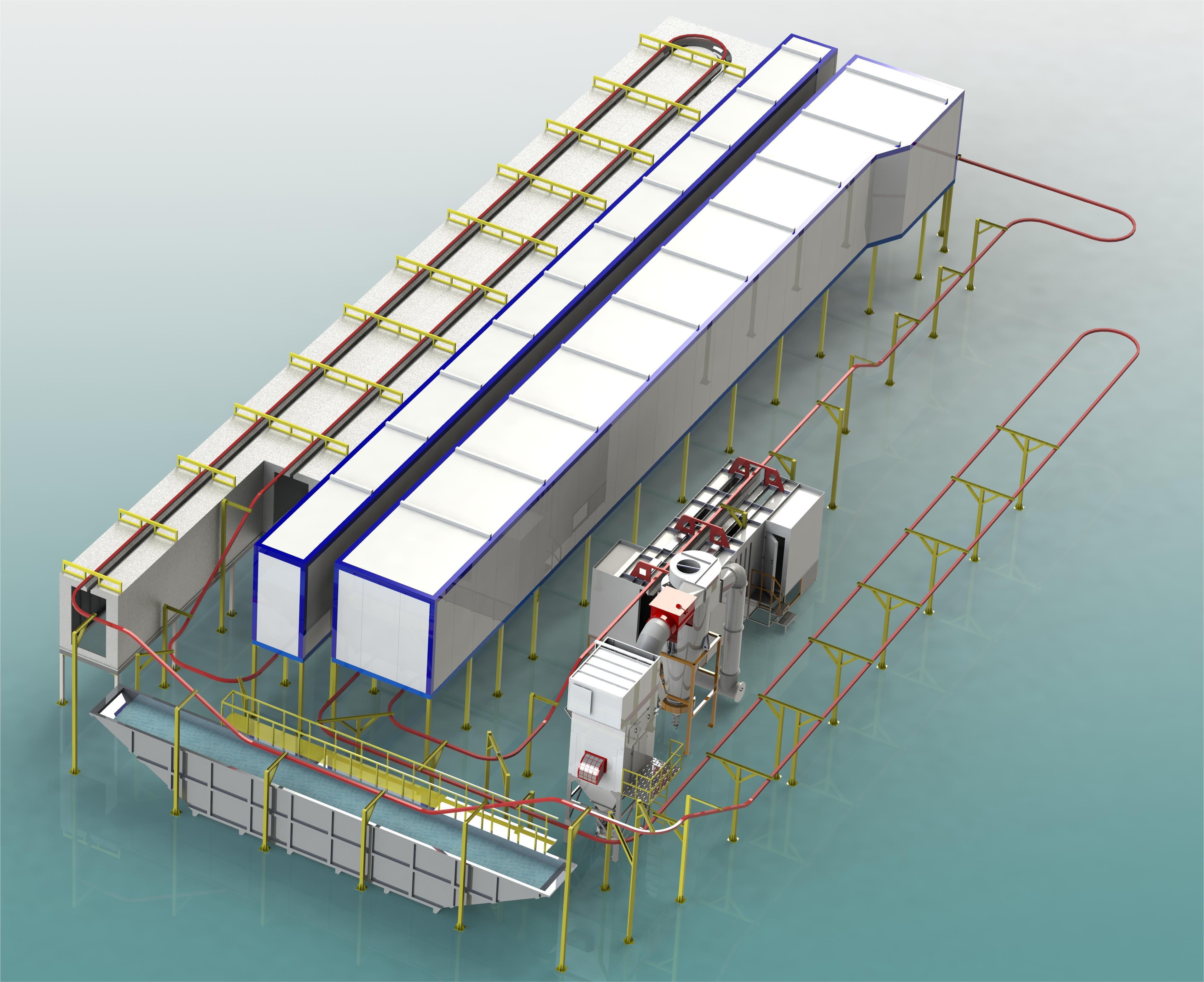

Modular Smart Coating System | Integrated M30 Twin-Tech

30%↑ Efficiency · Zero Manual Intervention · 90%↑ Powder UtilizationSmartLine Powder Coating System

Fully Automated Turnkey Solution | 45%↑ OEE vs. Traditional Lines

Certified by TÜV SÜD | 36 Months Warranty

| Module | Core Innovation | Industry Breakthrough |

|---|---|---|

| AI Coating Hub | Deep vision + M30 dual-head path optimization | Identifies 200+ part types (0.5s/part) |

| Nano Recovery System | Triple-stage PTFE filters (0.1μm precision) | 99.2% reclaim rate (1st to break 99%) |

| Quantum Curing Oven | Hybrid IR/convection + frequency control | 45%↓ energy vs. gas curing |

| Zero-Change Conveyor | Maglev rail + auto-release hangers | Color change ≤8 min (Industry: 45 min) |

The powder coating process will inevitably be a messy one, so you can expect to see contaminants such as dirt, oil, grime, rust, grit, and other forms of residue building up on your rack and parts. The reason why such contaminants are so undesirable is the fact that they are capable of causing flakes, bubbles, and cracks to form on the powder coating in the course of the curing process.

The best way to avoid these potential dangers will be to thoroughly clean out the parts and racks before you start the spraying process so that you eliminate any possible surface contaminants. The most effective cleaning methods include using chemical pretreatments and blasting followed by wipe-downs. An essential element of parts preparation includes making sure that all racks are properly grounded.

This is of vital importance to the safety of powder spray operators as it will keep them safe from potential short circuits and electrical risks. Rods and Faraday cages should be incorporated into the booth design and kept entirely free of any debris or residue, as these may interfere with their effectiveness.

Without these approaches, powder painters might have an unnecessarily difficult time performing their duties, especially when it comes to dealing with corners and tight angles.

As one of metal surface treatment methods, powder coating line is more and more used for many industries. Such as aluminum profiles, electric cabinets, racks,shelves, agricultural machinery, and other metal industries. There are many different kinds of powder coating line in the market, different supplier has different structure on powder coating line.

1.What products do you plan to spray, and what's the maximum size of them and the capacity requirement.

These three information affects the space of your factory needed.

① The capacity decides the type of the line you need: fully automated powder coating line, semi-automatic powder coating line or manual powder coating system.

② The maximum size of the products decide the size of the curing oven. Powder coating oven as one of the most important part of powder coating line, curing time will affects the scale of the line.

③ The products you plan to spray also decide the steps of the powder coating line. For example, whether the products need pretreatment system or pre-heating before powder coating. Different material of the products use different process and time of powder coating line.

2. The weight of products will affect the conveyor. We have different kinds of conveyor for powder coating line. From less than 1kg to more than 10 tons products, we could provide the most suitable solution for your business.

Previous:First

Next :Last

MINGFAN Import and Export Trade (Dezhou) Co., Ltd.

+86-18315884617Follow Us

Copyright © 2026 Dezhou Mingfan Coating Equipment Co., Ltd.All rights reserved.

If you have any queries, get in touch today! Don't hesitate. We try to take the extra step for our customer satisfaction.

| Product Picture | Product Name |

|

powder coating line |